A crankshaft is the heart of every diesel engine—and failure can result in catastrophic downtime and repair costs. Across Africa’s marine, power, and industrial sectors, onsite inspection of crankshafts is critical for ensuring continued reliability, identifying faults early, and avoiding unplanned breakdowns.

At Panesar Crankshaft Centre, we offer expert onsite crankshaft inspection services across Africa, using precision instruments and proven diagnostic techniques.

Why Onsite Crankshaft Inspection Matters

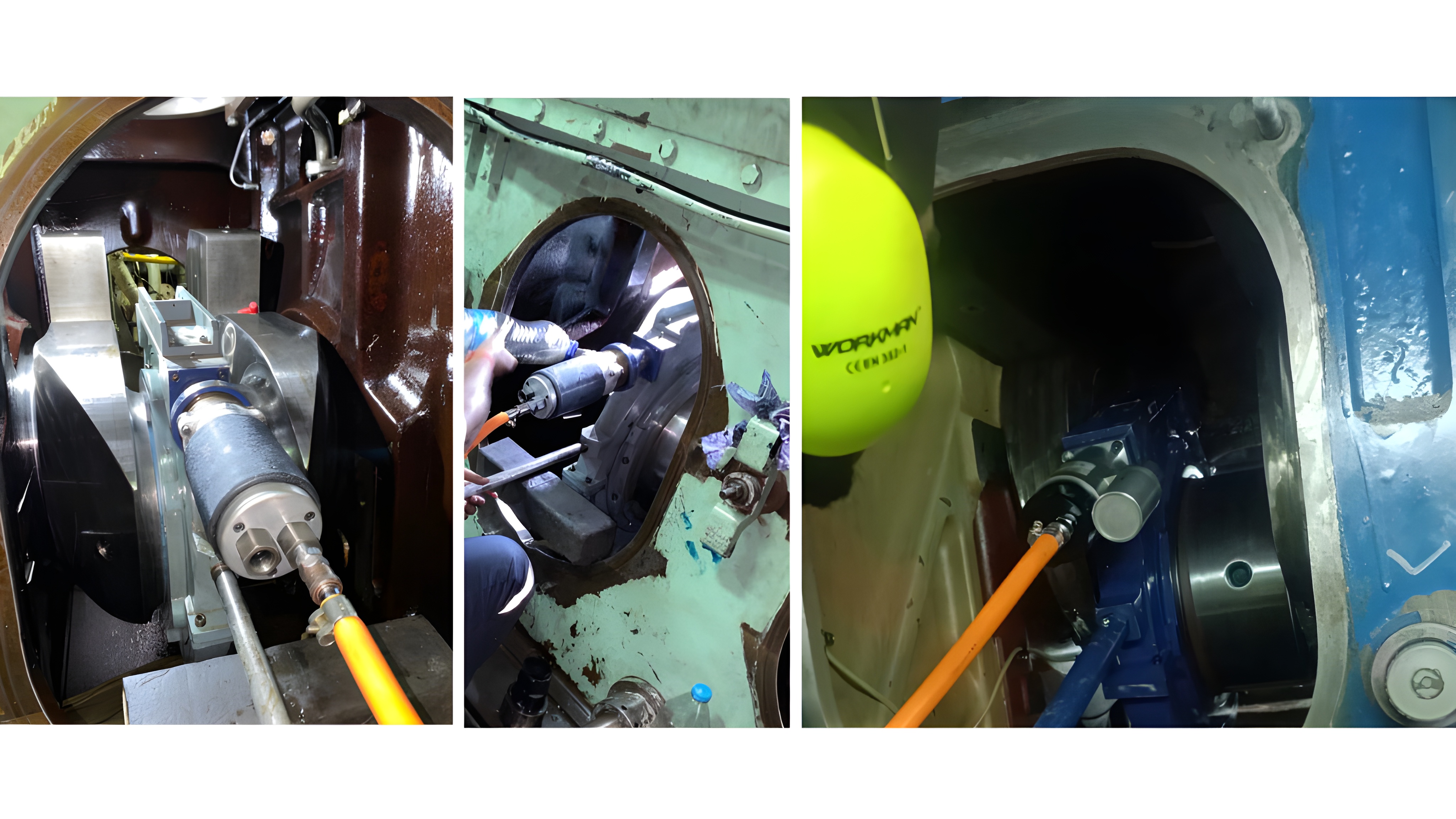

Removing a crankshaft for inspection can be costly, time-consuming, and impractical—especially for large engines in remote or offshore locations. Onsite inspection allows trained technicians to assess the crankshaft’s condition without dismantling the engine, saving time and avoiding unnecessary disruptions.

What Does Onsite Crankshaft Inspection Involve?

Our comprehensive inspection includes:

- Visual Examination: Checking for cracks, scoring, or surface defects

- Dial Gauge Measurement: Measuring journal runout and deflection

- Hardness Testing: Verifying material strength and wear resistance

- Magnetic Particle or Dye Penetrant Testing (MPI/DPI): Detecting surface cracks

- Journal Diameter and Ovality Checks: Confirming tolerances and geometry

- Vibration and Alignment Checks (if engine is operational)

All results are documented in a detailed report, enabling informed decisions on repair, grinding, or overhaul.

Industries That Benefit from Crankshaft Inspection in Africa

- Power generation (diesel, HFO, gas)

- Marine and shipping

- Oil & gas operations

- Mining and earthmoving

- Industrial backup generators and process plants

Whether it’s a power station in a remote region or a vessel at port, our inspection team can be deployed rapidly.

Benefits of Onsite Crankshaft Inspection

- Minimize downtime by identifying issues early

- Avoid unnecessary disassembly or shipping

- Plan repairs proactively before failure occurs

- Ensure safe operation of high-value machinery

- Support insurance and warranty claims with certified reports

What to Expect from Panesar Crankshaft Centre

- Qualified engineers and experienced inspectors

- Portable, calibrated tools and NDT equipment

- Fast mobilization to any location in Africa

- OEM-aligned procedures and reporting standards

- Recommendations on regrinding, metal stitching, or overhaul (if needed)

Preventative Maintenance Starts with Inspection

At Panesar Crankshaft Centre, we help clients extend crankshaft life, avoid unexpected failures, and maintain operational continuity. Our onsite crankshaft inspections provide actionable insights to keep your equipment running smoothly—no matter where it’s located.

Concerned about crankshaft condition?

Book an onsite inspection with our team and get a detailed status report—before small issues become major failures.

Panesar Crankshaft Centre — Precision inspection for Africa’s critical engine components.