In critical industrial and marine environments, engine downtime is costly. Traditional crankshaft repair methods involve dismantling, removal, and shipment—often leading to weeks of disruption. That’s why industries across Africa now rely on onsite crankshaft grinding services, eliminating delays while maintaining OEM repair standards.

At Panesar Crankshaft Centre, we deliver expert in situ crankshaft grinding across Africa’s power plants, marine vessels, refineries, and remote industrial sites—restoring crankshafts quickly and accurately, without engine removal.

What Is Onsite Crankshaft Grinding?

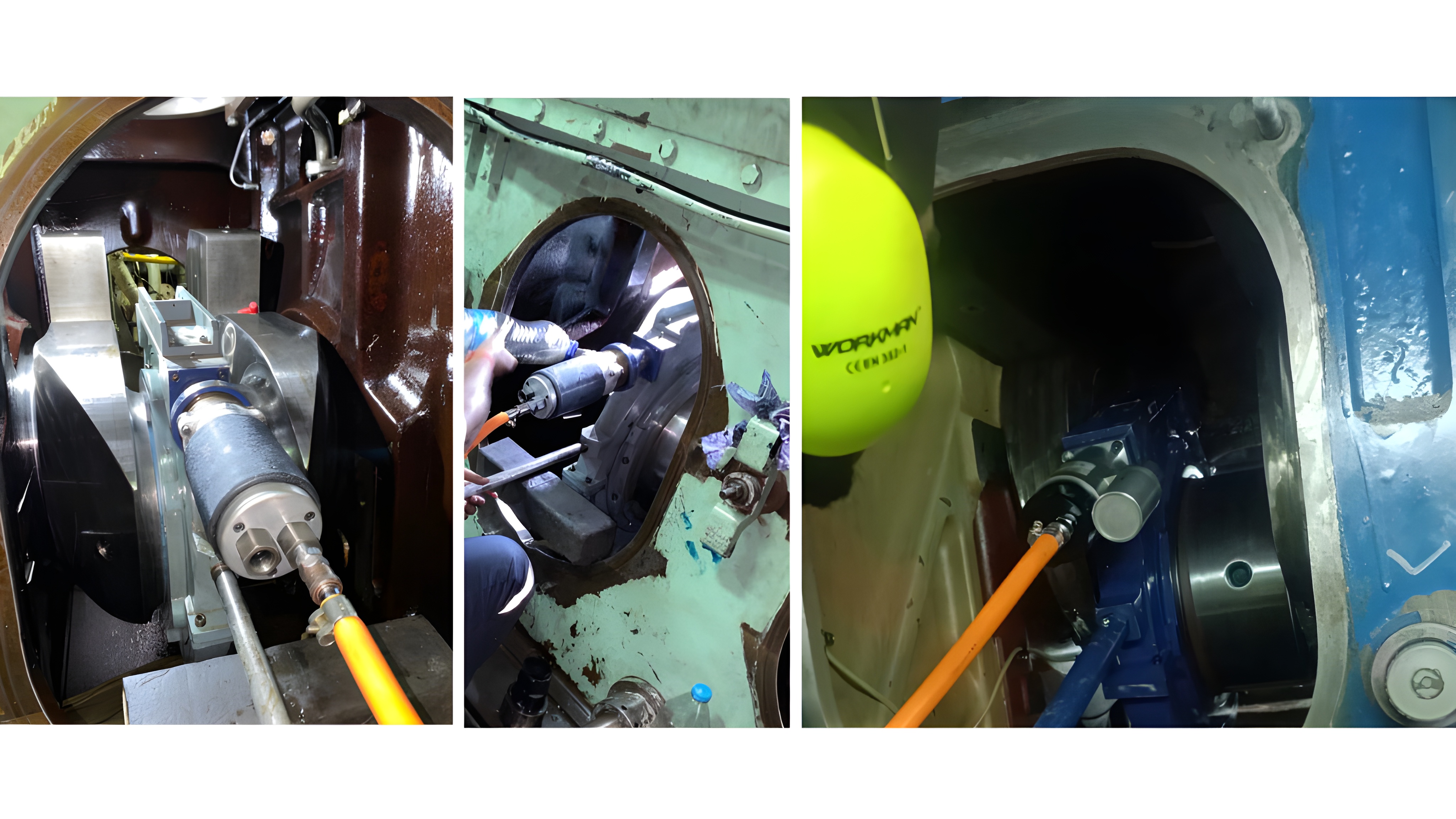

Onsite crankshaft grinding (also called in situ crankshaft grinding) is a process where technicians bring portable grinding equipment directly to the engine location. It allows for:

- Grinding of crankpins and main journals

- Restoration of journal diameter, roundness, and taper

- Surface polishing and dimensional reporting

- Elimination of the need to dismantle the engine or transport the crankshaft

This service is ideal for large marine engines, power gensets, and heavy-duty industrial machinery.

Common Problems Fixed by Onsite Grinding

- Journal wear, scoring, or pitting

- Ovality and taper due to prolonged use

- Overheating or bearing seizure damage

- Misalignment between crank journals

- Surface irregularities causing vibration

Industries Served Across Africa

We support clients in:

- Marine and shipping operations

- Diesel and gas power plants

- Oil & gas platforms and refineries

- Mining and earthmoving sectors

- Fertilizer and cement industries

Whether your engine is offshore, in a desert power station, or at a remote industrial hub—we come to you.

Our Onsite Crankshaft Grinding Capabilities

- Crankpin and main journal grinding (diameters up to 1500 mm)

- Surface finishes up to Ra 0.2–0.4 μm

- Journal polishing and fillet radius restoration

- Hardness testing and crack detection (MPI/DPI)

- Final inspection and dimensional reporting

Benefits of Onsite Crankshaft Grinding

- No engine removal – avoids transport and dismantling

- Fast turnaround – grinding completed in days, not weeks

- Minimized downtime – keep your engine in place

- Cost-effective – eliminate logistics and shipping costs

- OEM-level accuracy – restored to exact tolerances

Why Panesar Crankshaft Centre?

- Decades of crankshaft grinding experience

- Certified in situ machining technicians

- Portable grinding equipment for remote deployments

- Trusted by marine, industrial, and energy clients across Africa

- Emergency response teams available 24/7

Precision Repairs. Delivered Anywhere in Africa.

At Panesar Crankshaft Centre, we understand the urgency of crankshaft repairs. Our onsite grinding services are trusted by operators across Africa to reduce downtime, cut costs, and keep engines running without delay.

Need fast onsite crankshaft grinding?

Contact us now to schedule a site visit. We’ll restore your crankshaft where it sits—no removal, no shipping, no compromise.

Panesar Crankshaft Centre — Onsite crankshaft grinding for Africa’s marine, power, and industrial engines.