When critical rotating or structural equipment breaks down, in situ machining repair services provide fast, cost-effective solutions—without removing or transporting components. Across Africa’s power plants, industrial sites, and refineries, in situ machining restores precision and performance directly at the point of operation.

What Is In Situ Machining?

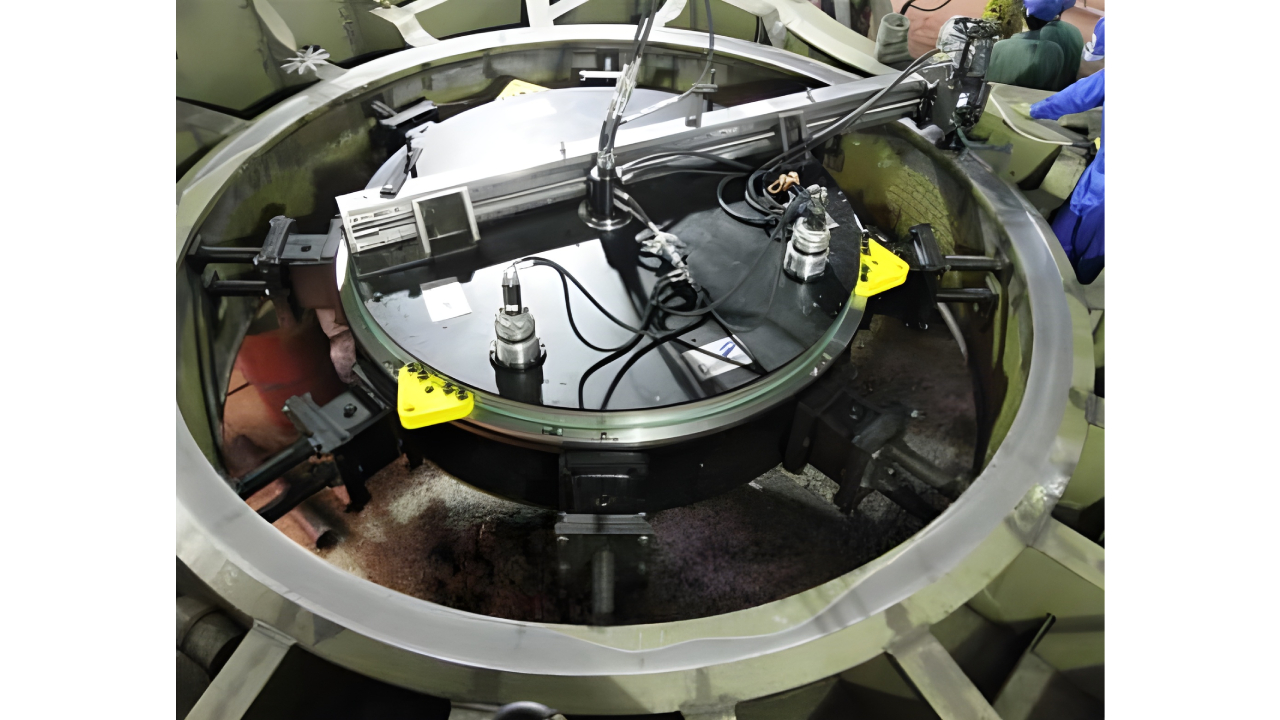

In situ machining refers to precision repair or re-machining work carried out on equipment while it remains in place. Using portable machine tools, technicians can perform high-accuracy repairs on shafts, journals, flanges, casings, and more—without dismantling or transporting heavy assets.

Key Benefits of In Situ Machining in Africa

- Minimized Downtime: Eliminate delays associated with disassembly and logistics

- Reduced Cost: Avoid shipping, lifting, and reinstallation expenses

- OEM Precision: Maintain tight tolerances using advanced mobile equipment

- Safer Repairs: No need to move large or delicate machinery

Common In Situ Machining Applications

- Shaft and journal grinding or turning

- Flange face machining

- Line boring and bore welding

- Keyway and slot machining

- Surface restoration of turbine, compressor, or engine components

Industries Relying on In Situ Machining Services

- Power generation (thermal, hydro, renewable)

- Oil & gas and petrochemical plants

- Mining and mineral processing

- Marine and offshore vessels

- Cement, steel, and heavy manufacturing

Panesar Crankshaft Centre delivers in situ machining services tailored to Africa’s unique industrial environments—remote sites, high-stakes downtime, and demanding operating conditions.

Why Choose In Situ Machining?

- Avoid long delays from overseas shipping

- Maintain operational continuity

- Extend equipment lifespan with timely intervention

- Handle emergency breakdowns or scheduled shutdowns

- Ensure alignment and fit with adjoining components

What to Look for in an In Situ Machining Provider

- Certified and experienced field technicians

- Specialized mobile machining and measuring tools

- Capability to handle large-diameter or critical components

- Engineering support for diagnostics and reverse engineering

- Responsive deployment and 24/7 availability

Panesar Crankshaft Centre: In Situ Machining Experts in Africa

At Panesar Crankshaft Centre, we bring world-class in situ machining repair services across Africa—supporting industries that demand speed, accuracy, and reliability.

From power stations to marine vessels, we repair damaged components with minimal disruption—helping clients reduce downtime, save money, and extend machinery life.

Need in situ machining services for critical repairs?

Contact us today to schedule a site assessment or emergency response.

Panesar Crankshaft Centre — Bringing precision machining to Africa’s industrial frontlines.