Wartsila engines power critical operations in marine, power generation, and offshore sectors—often in remote or high-demand environments where downtime is not an option. When crankshaft damage occurs, in situ crankshaft grinding offers a fast, reliable, and cost-effective solution—without the need for engine removal or costly transport.

At Panesar Crankshaft Centre, we specialize in onsite crankshaft grinding for Wartsila engines, restoring journal surfaces to original OEM specifications using portable, high-precision equipment.

Why Insitu Crankshaft Grinding is Essential

Crankshaft damage—caused by bearing failure, misalignment, or overheating—can lead to severe engine inefficiency or total failure. Insitu grinding allows technicians to restore crankshaft geometry onsite, eliminating logistics delays and reducing costs.

Wartsila Engine Models We Support

- Wartsila 18V32 / 12V32 / 16V32

- Wartsila 46 Series

- Wartsila 20 / W20DF / W34DF

- Wartsila-Sulzer RTA and RT-flex models

- Wartsila dual-fuel and gas engines

Whether the engine powers a vessel, floating power station, or industrial generator, we deliver OEM-aligned grinding solutions.

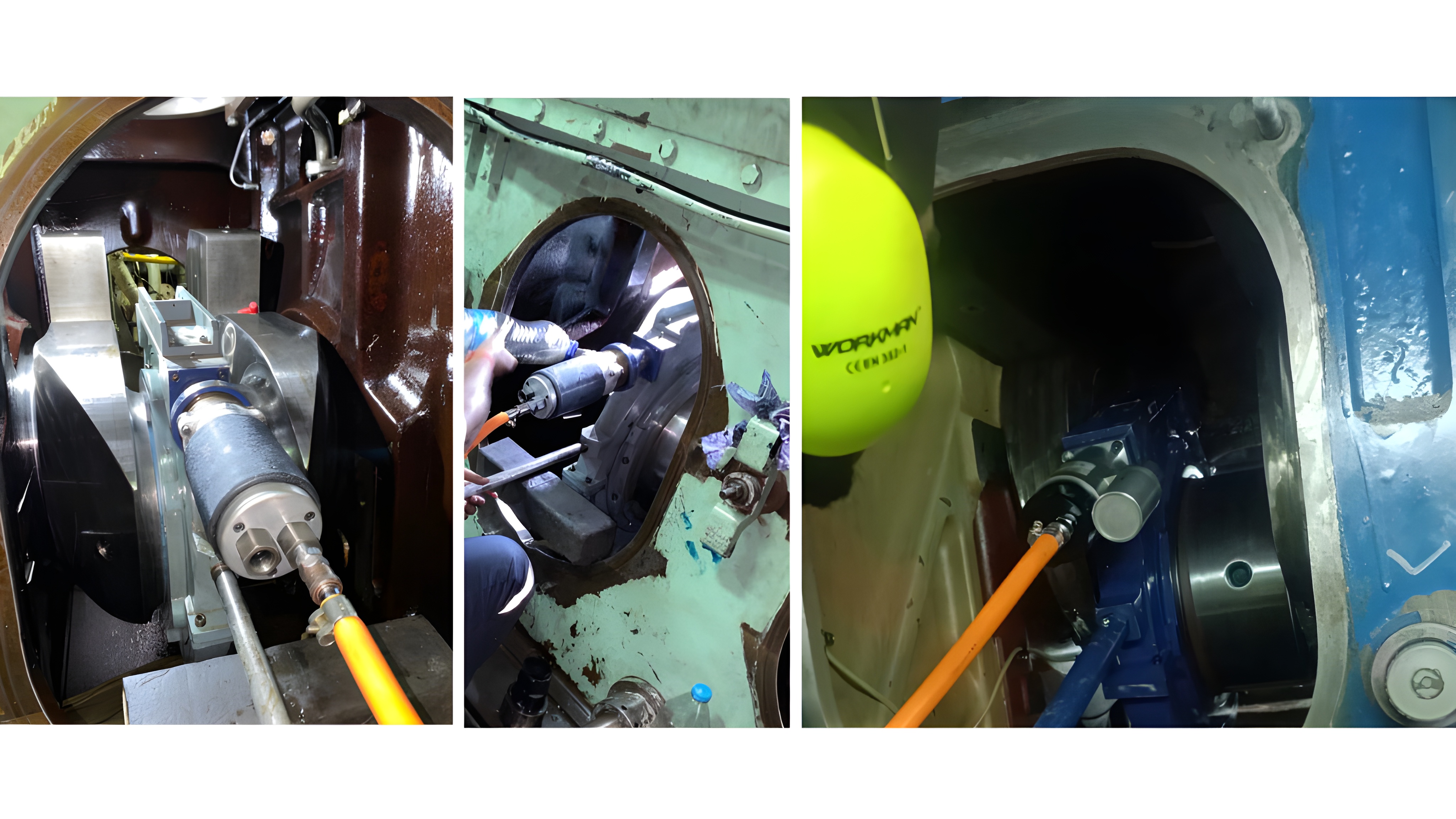

Our Insitu Crankshaft Grinding Process

- Initial inspection: journal wear, runout, and ovality

- Setup and alignment of portable grinding machine

- Precision grinding to restore diameter and roundness

- Final polishing for correct surface finish

- Post-repair measurements and hardness testing

- Comprehensive service report and recommendations

All procedures follow Wartsila technical standards and international quality protocols.

Key Benefits

- No need for engine block or crankshaft removal

- Faster turnaround compared to full overhaul

- Restores crankpin journals to OEM specifications

- Reduces vessel or plant downtime

- Ideal for emergency or planned repairs

- Proven success with diesel, HFO, and dual-fuel engines

Industries We Serve Across Africa

- Marine and shipping

- Power generation (diesel, HFO, gas)

- Offshore oil & gas

- Mining and industrial operations

We provide fast deployment and 24/7 service support to ensure your equipment stays operational.

Why Choose Panesar Crankshaft Centre

- Experienced technicians with Wartsila engine expertise

- High-accuracy portable grinding equipment

- In-house NDT and hardness testing

- Detailed reporting for insurance or compliance

- Recommendations for metal stitching or regrinding if needed

Ready to Restore Your Wartsila Engine?

Don’t wait for failure. Restore crankshaft integrity and minimize downtime with our onsite grinding services—available anywhere in Africa.

Need emergency crankshaft grinding for your Wartsila engine?

Contact our team for immediate response and expert service.

Panesar Crankshaft Centre — Restoring precision. Delivering uptime.