Large engines are critical to power generation, marine propulsion, mining operations, and heavy industry throughout Africa. When a crankshaft becomes worn, scored, or misaligned, in situ crankshaft grinding repair is the fastest and most economical solution—restoring performance without removing the crankshaft.

What Is In Situ Crankshaft Grinding?

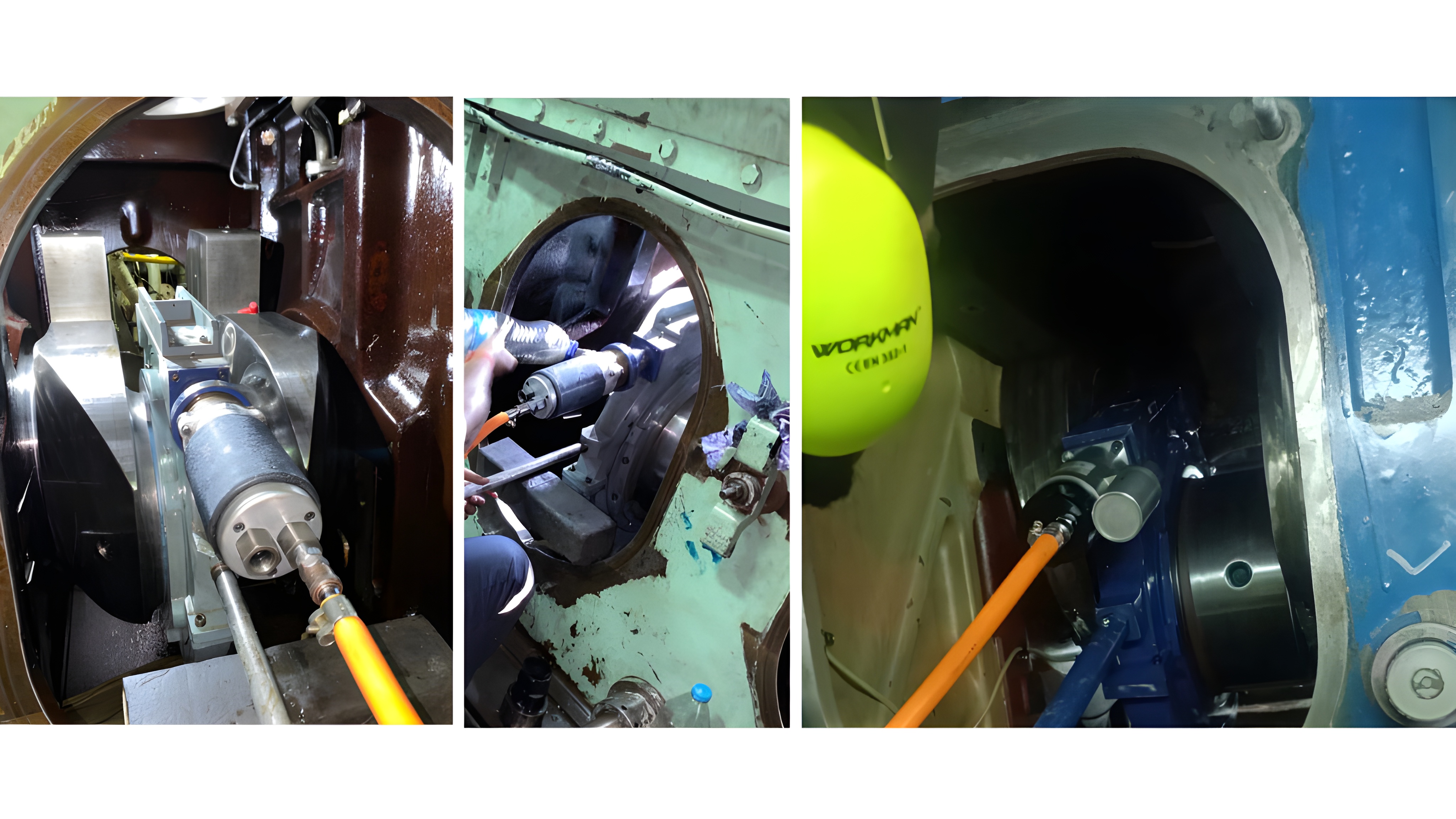

In situ crankshaft grinding is the process of regrinding damaged crankshaft journals while the crankshaft remains installed in the engine block. Specialized portable grinding equipment is used to restore journal geometry and surface finish—eliminating the need for costly dismantling or overseas repair.

Why It Matters in Africa

Transporting crankshafts for repair can be time-consuming, expensive, and risky—especially for:

- Power stations in remote regions

- Marine vessels operating at port

- Refineries and offshore rigs

- Heavy-duty generators and engines in mining

With in situ repair, your operation stays on-site, and downtime is minimized.

Common Crankshaft Issues Resolved by In Situ Grinding

- Scored or worn crankpin and main journals

- Ovality and taper on journal surfaces

- Surface cracks or fatigue marks

- Misalignment or vibration-causing damage

- Bearing seizure and localized heat spots

Industries That Rely on In Situ Crankshaft Grinding

- Thermal and hydroelectric power generation

- Oil & gas plants and FPSOs

- Marine and ship engines

- Mining and earthmoving equipment

- Industrial diesel and gas generators

Whether diesel or gas-powered, two-stroke or four-stroke—Panesar Crankshaft Centre provides precision grinding tailored to your engine’s specifications.

Benefits of In Situ Crankshaft Grinding Repair

- No disassembly or removal required

- Rapid service delivery—ideal for emergency breakdowns

- Cost savings on transport and logistics

- OEM-level precision using CNC-controlled grinding tools

- Extended crankshaft and engine life

Choosing the Right Crankshaft Grinding Provider

Make sure your partner offers:

- Highly experienced field technicians

- Portable grinding equipment for various crankshaft sizes

- Vibration analysis, journal inspection, and hardness testing

- Support for emergency mobilization

- Proven results across multiple engine brands and models

Panesar Crankshaft Centre: In Situ Crankshaft Grinding Experts Across Africa

At Panesar Crankshaft Centre, we specialize in in situ crankshaft grinding repair services for engines operating in Africa’s most demanding environments.

Our mobile teams respond quickly to restore damaged crankshafts in power plants, marine vessels, and industrial engines—minimizing downtime and restoring peak performance.

Crankshaft damage slowing you down?

Contact us today for expert in situ grinding and fast turnaround—no removal, no delays.

Panesar Crankshaft Centre — Restoring crankshaft integrity across Africa, one engine at a time.