MAN engines are trusted worldwide for their performance in marine vessels, power plants, and industrial equipment. But when crankshaft damage occurs, even the most robust engine is at risk of unplanned shutdowns. That’s where in situ crankshaft grinding comes in—restoring crankshaft surfaces to full functionality without engine removal.

At Panesar Crankshaft Centre, we provide specialized onsite crankshaft grinding for MAN engines across Africa, using precision equipment and OEM-guided procedures.

Why In Situ Grinding for MAN Engines?

Crankshafts can suffer from wear, scoring, heat damage, and journal misalignment due to bearing failure or lubrication issues. Replacing or removing a crankshaft is expensive and time-consuming. With onsite grinding, the crankshaft is repaired in place—minimizing cost and downtime.

Supported MAN Engine Models

Our team is equipped to service a wide range of MAN diesel and dual-fuel engines, including:

- MAN B&W 6L23/30, 8L28/32, 9L48/60

- MAN 32/40, 48/60CR, and 51/60DF engines

- MAN L and V series trunk piston engines

- MAN two-stroke marine engines

- Stationary MAN engines used in power generation

Whether on a cargo vessel, offshore platform, or inland power station, we deliver precision grinding aligned with MAN’s technical specifications.

Our Onsite Crankshaft Grinding Services

- Journal wear inspection and damage assessment

- Runout, ovality, and deflection measurements

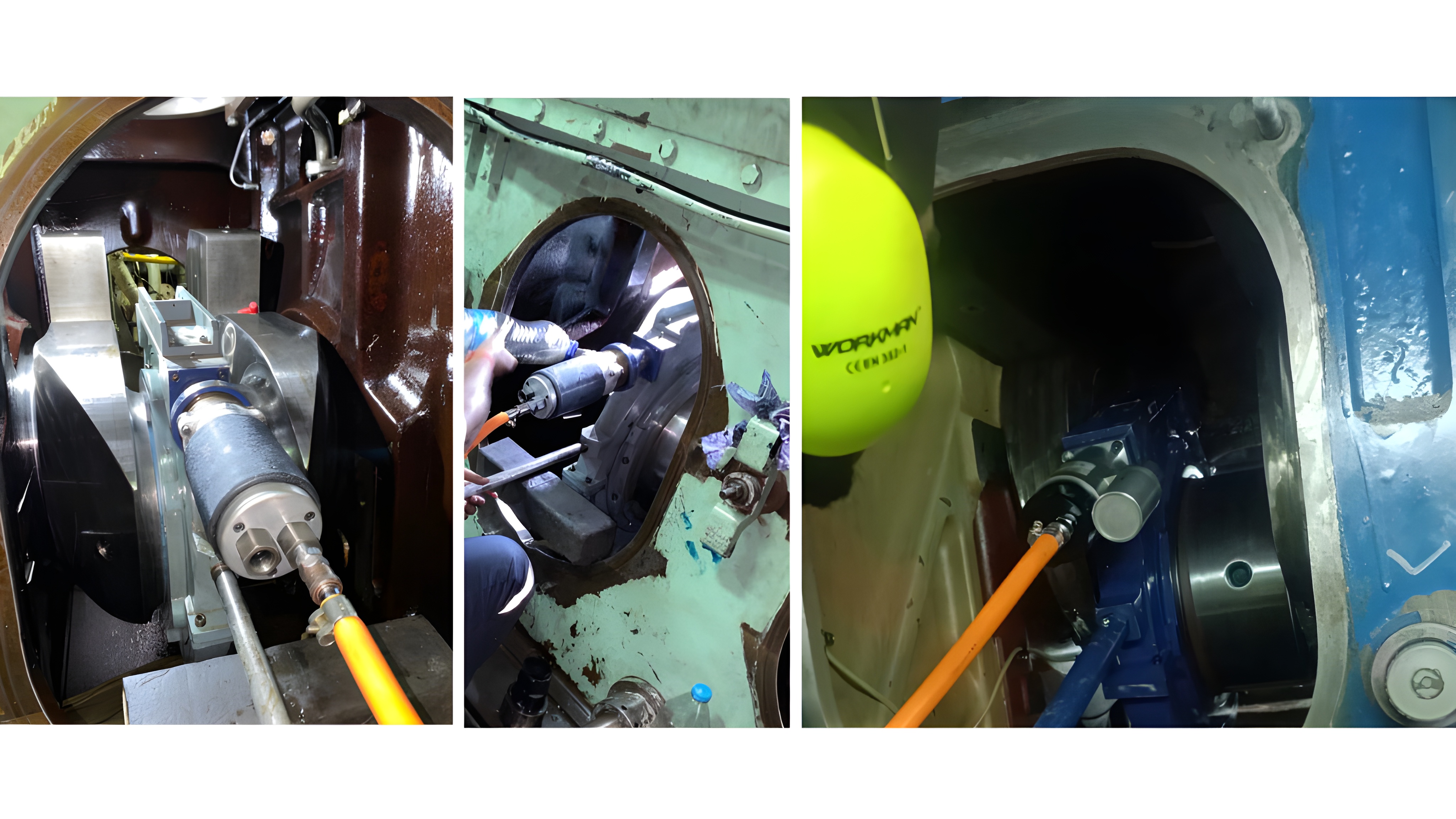

- Setup of portable grinding machine

- Grinding to restore journal diameter and roundness

- Final polishing and surface finish optimization

- Post-repair NDT and hardness testing

- Detailed service report with recommendations

All work is conducted in compliance with MAN engine standards and ISO guidelines.

Benefits of Onsite Crankshaft Grinding

- No need to dismantle or remove the crankshaft

- Faster turnaround than workshop repairs

- Restore journals to exact OEM specifications

- Extend engine life and reduce risk of future failure

- Cost-effective, especially in remote or offshore locations

- Ideal for emergency breakdown response or scheduled maintenance

Industries We Serve

- Marine and shipping operators

- Offshore oil & gas platforms

- Diesel power plants and independent power producers

- Industrial backup generators

- Mining and earthmoving equipment

We deploy rapidly across Africa with full toolkits, experienced technicians, and portable diagnostic and grinding units.

Why Panesar Crankshaft Centre?

- Over two decades of experience with MAN crankshafts

- Calibrated, high-precision grinding equipment

- OEM-style inspection and documentation

- Full support for metal stitching, alignment, and regrinding if required

- Certified NDT and hardness testing on-site

Keep Your MAN Engine Running Smoothly

If your MAN engine is showing signs of crankshaft damage—don’t wait for failure. Our in situ crankshaft grinding service ensures fast, accurate repairs without downtime or disassembly.

Need urgent help with your MAN engine?

Book an inspection and grinding service today, and get your equipment back to full performance.

Panesar Crankshaft Centre — Experts in crankshaft restoration for MAN engines.