Daihatsu marine engines are widely used in commercial vessels, tugboats, ferries, and port service ships due to their reliability and compact design. However, when crankshaft journals become worn or damaged, even a dependable engine can grind to a halt—unless fast, onsite crankshaft grinding is available.

At Panesar Crankshaft Centre, we offer in situ crankshaft grinding for Daihatsu engines, helping operators restore engine performance quickly—without dismantling or removing the crankshaft.

Why In Situ Crankshaft Grinding Matters

Crankshaft damage caused by bearing failure, overheating, or oil starvation can lead to misalignment and reduced engine efficiency. Traditional workshop repairs require engine disassembly and shipping delays. Our onsite grinding method allows precision reconditioning while the crankshaft remains in place—minimizing cost and downtime.

Daihatsu Engine Models We Support

We service a wide range of Daihatsu engines, including:

- Daihatsu 5DK, 6DK, 8DK series

- Daihatsu 6DE18, 6DE20, 6DL series

- Daihatsu 5DC, 6DC engines

- Daihatsu dual-fuel and HFO marine models

- Auxiliary and propulsion applications

Whether the engine is installed in a coastal cargo vessel, fishing trawler, or port generator, we deliver reliable results based on OEM specifications.

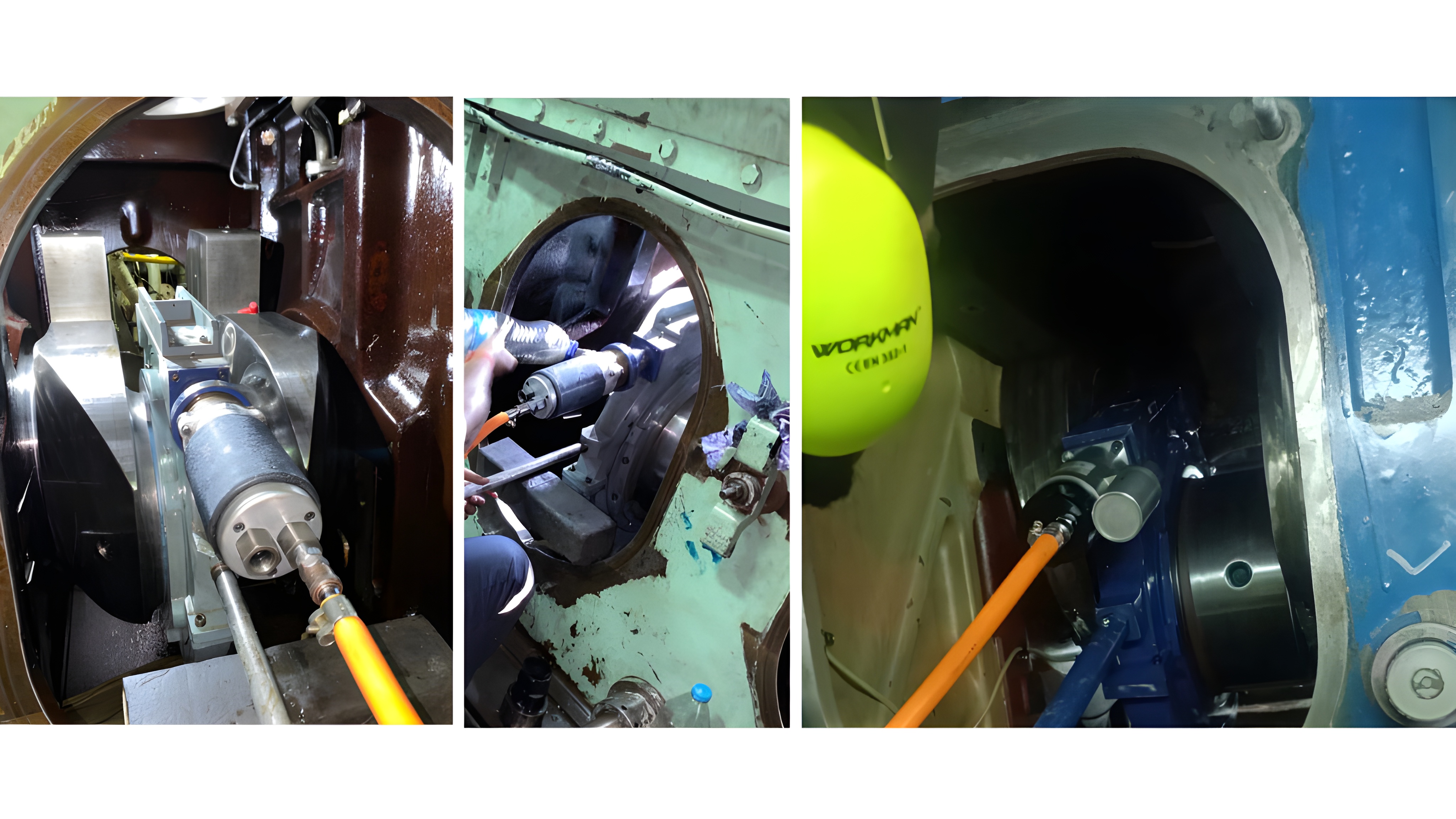

Our Crankshaft Grinding Process

- Visual inspection and journal damage assessment

- Measurement of journal ovality, taper, and runout

- Setup and alignment of onsite grinding machine

- Precision grinding and polishing to required tolerances

- Post-repair hardness testing and dimensional verification

- Detailed service report with recommendations

All work is performed in line with Daihatsu engine tolerances and ISO standards.

Key Benefits

- No need to remove the crankshaft or engine block

- Accurate restoration of journal surfaces

- Fast turnaround—even at remote ports or onboard vessels

- Extended engine service life

- Cost-effective alternative to replacement

- Supports insurance or classification reports with full documentation

Trusted by Marine Operators Across Africa

We support:

- Cargo ships

- Fishing fleets

- Ferries and RoRo vessels

- Offshore supply vessels

- Coastal and harbor tugs

Our team mobilizes quickly across Africa with portable equipment and experienced engineers to keep your vessel in service.

Why Choose Panesar Crankshaft Centre?

- In-depth experience with Daihatsu engines

- Calibrated portable crankshaft grinding machines

- Certified NDT and hardness testing on-site

- OEM-style documentation for class and insurers

- 24/7 emergency deployment options

Restore Your Daihatsu Crankshaft Without Delay

If your Daihatsu engine is down due to crankshaft journal wear, don’t wait for major damage. Our in situ crankshaft grinding service helps you avoid expensive downtime and ensures your engine is back in service—safely and quickly.

Contact us today for inspection and grinding service across Africa.

Panesar Crankshaft Centre — Fast, accurate crankshaft repairs for Daihatsu marine engines.